Sales Hotline:

18970145687

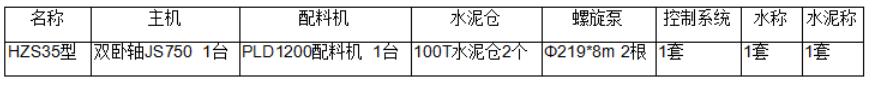

[35 basic configuration of mixing station]

[35 basic configuration of mixing station] [product introduction]

HZS35 concrete mixing station is a small-scale concrete mixing station, which is generally applicable to the concrete construction of industrial, civil buildings, highways, railways, bridges, electric power, water conservancy, ports, wharves, airports, prefabrication plants and other projects. It is a simple mixing station.

HZS35 concrete mixing station is a complete set of concrete mixing equipment composed of feeding, batching, mixing, electrical control and other parts. HZS35 concrete mixing plant, with a theoretical production rate of 35m3 / h, is a complete set of automatic concrete mixing equipment composed of feeding, batching, mixing, electrical control and steel structure components.

The main features of HZS35 concrete mixing plant are as follows:

1. HZS35 concrete mixing plant adopts combined structure and modular unit, which is very convenient for installation and relocation.

2. Js750 double horizontal shaft forced concrete mixer is used for mixing main machine and aggregate lifting, with good mixing quality and high efficiency.

3. Pld1200 concrete batching machine is used for aggregate batching, with accurate measurement and high production efficiency.

4. The powder, water and admixture in the mixing station are all measured by electronic scale, with high batching accuracy.

5. The water supply system of the concrete mixing plant adopts the principle of siphon type water pump to increase the water flow rate and spray evenly.

6. The electrical control system of the concrete mixing plant is made of high-quality components with reliable performance, which can be controlled manually / automatically and is easy to operate.

HZS35 concrete mixing station has the advantages of centralized mixing of cement concrete:

(1) The centralized mixing of cement concrete is convenient for the strict control of concrete mix proportion and the guarantee of concrete quality, which fundamentally changes the inaccurate situation of on-site decentralized mixing

(2) The centralized mixing of cement concrete is conducive to the adoption of automation technology, which can greatly improve labor productivity, save labor and reduce costs;

(3) It is unnecessary to install mixing equipment, stack sand and stone materials and store cement in the construction site for centralized mixing, so as to save the site and avoid waste of raw materials.

Annual output and profit of building a 35 mixing plant

The complete set of equipment for the concrete mixing plant with an annual output of 35 cubic meters has good investment profitability. The annual output of concrete is about 72000 cubic meters (8 hours per day, 300 working days per year), and the annual sales volume is 36000 cubic meters. The profit is about 2.74 million yuan / year

项目 | 单价 | 数量 | 总计 |

年度经营收入 | 320元/方 | 3.6万方 | 1152万元 |

材料成本 | 200元/方 | 3.6万方 | 720万元 |

能源及维保费用 | 12元/方 | 3.6万方 | 43.2万元 |

人工管理费用 | 4.5万元/人/年 | 10人 | 45万元 |

营业税 | 6% | —— | 69.12万元 |

年度经营利润 | —— | —— | 274万元 |

TEL:

18079713117

TEL:

18079713117

Copyright © Ningdu xingye machinery manufacturing co. LTD Technical support:

Address:18079713117industrial park, ningdu county, ganzhou city, jiangxi province