Sales Hotline:

18970145687

[product introduction]

WBZ series stabilized soil mixing station equipment is an economic and practical stabilized soil plant mixing equipment, with mature product structure, complete varieties and specifications, stable and reliable performance and quality.

Product characteristics of stabilized soil mixing station:

1. The equipment can mix cement stabilized soil, lime stabilized soil, gravel stabilized soil and other base stabilization materials;

2. The equipment is suitable for road, airport, railway, municipal construction, etc. to produce various specifications of stabilized soil base materials;

3. Adopt double horizontal shaft forced mixer without liner, dense small pulp leaves and large linear speed scheme, so that the materials can be rapidly promoted in the "boiling" state, with high productivity, continuous and stable mixing and uniform production process, without replacing liner, long service life and low maintenance cost;

4. Single motor drive reducer, large gear synchronous transmission, stable and reliable operation, shock and vibration resistance, strong anti overload ability, long service life;

5. The unique form of water supply ensures that the water supply is uniform, stable and effective. Water mist can effectively reduce dust pollution and effectively remove stable soil lumps;

6. The special large mouth screw feeder for powder avoids the phenomenon that the impeller feeder is easy to be blocked due to dampness in the past, makes the dust measurement more reliable, stable, even and continuous, effectively reduces the waste of powder and the scrap of finished materials, and stabilizes the cost control of materials more accurately;

7. Various powder supply modes can be selected: manual unpacking or bulk cement or bucket elevator;

8. It adopts computer speed regulation or frequency conversion electronic speed regulation, with uniform and continuous material supply, strong anti-interference ability, accurate ratio and simple operation;

9. The system has the following functions: shutdown, startup process management and status detection, fault alarm, overload alarm and undervoltage protection, manual, semi-automatic and full-automatic operation modes, which can store the ratio, output and other data, and can output and print statistical reports. It provides strong support for site management, scheduling and monitoring;

10. The door of the finished product bin can be opened single or double, which is convenient to use. There are 6, 8 and 10m3 volumes to choose from;

11. The fully sealed and air-conditioned control room improves the comfort of operators and reduces the labor intensity of operation;

12. Select high-quality electrical components, so that you can use them safely;

13. You can choose from a variety of structural forms or make them according to your requirements.

[product configuration]

Wbz300 computer metering frequency conversion speed regulating cement stabilized macadam mixing station configuration

(1) Complete machine: the total power is about 100kW

Particle size of mixed aggregate: 60mm

Powder measurement accuracy: ± 0.5-1%

Aggregate measurement accuracy: ± 0.5-1%

Production capacity: 100-450t / h

Control form: manual and automatic double control

(2) Aggregate supply system:

1. 4 aggregate hoppers with capacity of 10m3 / hopper, each hopper is equipped with lattice screen and baffle; 4 vibrators, 1.1kw/hopper.

2. Measuring device: computer belt scale.

System accuracy: ± 0.5-1%; measurement method: computer measurement, variable frequency speed regulation.

Measurement range: 0-300t (each scale)

3. Quantity of belt scale: 4 sets, motor power of belt scale: 4kw

Belt scale width: 10M

(3) 1 horizontal belt conveyor, 39.6m long

Belt conveyor belt width 800m, belt conveyor motor Power 1KW

(4) Powder supply system:

1. 1 cement bin 100t, diameter 30m

2. Powder metering system: 1 screw electronic scale.

Motor power: 4kw

Measuring accuracy: ± 0.5-1%; measuring range: 0-50t/h

3. One speed regulating screw conveyor with diameter of 250m and length of 3500m,

Motor power 4kw, variable frequency speed regulation.

(5) Water supply system: 1 water tank with a volume of 6m3; submersible pump flow of 40m3, motor power of 2.2kW

(6) Mixing device: production capacity: 100-450t / h;

Form: double horizontal axis forced continuous type; allowable particle size: 60m;

Motor power: 45KW; number of blades: 56, mixing arm 28 pairs;

1 reducer: jzq650; effective mixing length: 2800m

(7) One inclined belt conveyor, 41m in length and 800m in width. Lifting height: 5m;

Motor power: 1kW; installation angle: 18 °

(8) Finished product Silo: silo volume 8m3; discharge height 3.5m;

Width of material conveying channel: 3.7m; driving mode of bucket door: pneumatic; opening control mode of bucket door: Electric; 1 vibrator, power: 1.1KW

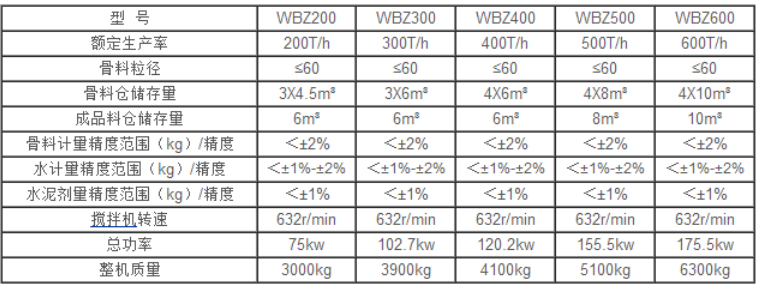

[technical parameters]

TEL:

18079713117

TEL:

18079713117

Copyright © Ningdu xingye machinery manufacturing co. LTD Technical support:

Address:18079713117industrial park, ningdu county, ganzhou city, jiangxi province