Sales Hotline:

18970145687

[product introduction]

Wbz700 stabilized soil mixing station adopts computer frequency conversion and electric control technology, stable metering system and mature production and processing mixing experience; the computer control process of production is realized for the integration of machinery and electricity from raw materials to finished product output. One machine is multi-purpose, and the replacement ratio can prepare a variety of stabilized soil base materials such as "cement stabilized macadam, lime fly ash macadam, cement / lime improved soil, a / B group filler, Graded Macadam, ordinary stabilized soil", so as to meet various demands of the market. Wbz700 stabilized soil mixing station can have 6 aggregate buckets, 4 kinds of powder silos, arch breaking device, bag cement elevator, cement bucket, the structure form has "one" shape structure, and "L" shape structure can be selected and combined as required. It can also be made according to your requirements. The production capacity is from 300t / h to 800t / h. From the reference guidance at the initial stage of station construction, foundation treatment, equipment installation to production commissioning, including the later equipment system upgrading and updating, as well as the application of new technology and new process. "Easy to use, durable, low failure rate, continuous high-speed operation and low operation cost" quality

Wbz700 stabilized soil mixing station is the base material mixing equipment of the construction unit, with excellent performance, reasonable structure, reliable quality, convenient use, easy maintenance and high productivity. With manual and automatic selection, the whole set of equipment only needs to be equipped with one operator.

The equipment mainly consists of system:

1. Batching supply system: sub hopper, adjustable speed (variable frequency) metering belt conveyor, belt conveyor.

2. Cement material supply system: Cement bin (cement hopper), speed control (frequency conversion) metering screw conveyor, screw electronic scale conveyor.

3. Automatic water supply system: water tank, water pump, pipeline, (water flow meter), sprinkler.

4. Mixing system: motor reducer, double horizontal shaft continuous mixer.

5. Storage bin device system: double discharge storage bin, inclined belt conveyor, air compressor.

6. Electrical system: operation control cabinet, operation room, air conditioner.

7. Metering control system: electronic accessories, electromagnetic (frequency conversion) speed regulation, microcomputer control manual, automatic two forms.

[equipment features]

1. Excellent mixing performance.

The mixer adopts the forced structure of double horizontal shafts without lining plate, with strong mixing capacity and high mixing uniformity. The mixer is suitable for various types of stabilized soil and sand. The flexible discharge port can easily resolve the contradiction between productivity and finished material uniformity, and greatly improve the usability of the equipment.

2. Good maintenance performance.

Each maintenance and repair part is equipped with a platform, which is intuitive, visible and has enough operation space, convenient for inspection and repair operation.

3. High reliability.

The mixer with unique shaft end support and seal greatly improves the working reliability of the equipment.

4. Perfect industrial design.

The industrial design idea runs through the whole product design process. The design combines ergonomics and aesthetics organically to make the whole machine beautiful and generous in shape, reasonable in structure layout and pleasant in color.

5. Accurate measurement performance.

The control system, which is composed of sensors and computers, has strong anti-interference, stable and reliable operation, and can complete the measurement control in a very accurate and timely manner.

6. Simple operation performance.

The whole machine can not only be controlled automatically, but also can be controlled semi automatically or manually. The operation is simple and easy to master. The calibration and adjustment of the weighing system is also very simple, which does not require complex parameter settings. The computer has a good man-machine interface, which makes the operation intuitive and convenient. At the same time, it can store and print report materials.

7. Flexible combination and arrangement.

Adopting the unit design concept, batching machine, aggregate belt conveyor, cement supply system, etc. can be combined flexibly according to the needs of users. According to the size of the site, the layout of the whole machine can be either "one shape" or "L shape" to meet the diversified needs of users.

8. With multiple working conditions and wide regional configuration, there are optional powder coal proportioner and digestion lime proportioner with forced arch breaking device to meet the needs of lime fly ash grading. 1-20T bagged cement bin is also provided to meet the supply demand of bagged cement under different working conditions.

9. Good use economy.

The non liner mixer uses the material static layer between the mixing blade and the mixing cylinder as the flexible wear-resistant layer instead of the rigid alloy wear-resistant layer, which can effectively avoid accidents such as blocking, chipping and jamming, reduce power loss, and improve the reliability and use economy of the mixer.

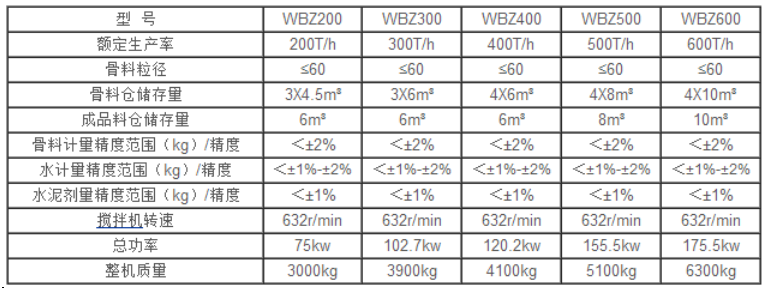

[technical parameters]

TEL:

18079713117

TEL:

18079713117

Copyright © Ningdu xingye machinery manufacturing co. LTD Technical support:

Address:18079713117industrial park, ningdu county, ganzhou city, jiangxi province